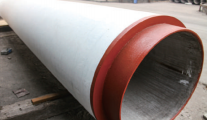

Ductile Iron Pipe

Ductile Iron Pipe (DIP), also known as Nodular Cast Iron Pipe, is a revolutionary piping material developed in the 1950s. By adding magnesium alloy to molten iron, the graphite within the iron matrix forms spherical nodules instead of flakes, achieving a perfect balance of ductility (like steel) and corrosion resistance (like traditional cast iron).

Design Life: 50–100 years, widely used in critical infrastructure.

Global Adoption: Over 70% of water supply networks in Europe and North America use DIP.

Key Features & Advantages

|

Feature |

Technical Details |

Benefit |

|

Ultra-High Strength |

Tensile strength ≥420 MPa, yield strength ≥300 MPa, 3× stronger than gray cast iron. |

Resists ground pressure, traffic loads, and seismic forces. |

|

Superior Flexibility |

Minimum elongation rate 10%, can bend up to 3°–5° without cracking. |

Adapts to soil movement and installation misalignment. |

|

Corrosion Defense |

- Exterior: Zinc spray (≥130 g/m²) + asphalt coating. |

Survives harsh soils and aggressive fluids (pH 5–12). |

|

Leak-Free Joints |

TYTON® push-on joints or mechanical joints (M/F type), tested to 1.5× working pressure. |

Reduces water loss and maintenance costs. |

Applications

|

Field |

Project Examples |

Regional Cases |

|

Municipal Water |

Tokyo Metropolitan Water Supply (Japan), Thames Water (UK), Beijing Water Authority (China). |

DN1200 pipes for urban mains with 6.0 m/s flow rate. |

|

Wastewater |

Singapore Deep Tunnel Sewerage System, Los Angeles Sanitation District. |

Epoxy-lined pipes for corrosive sewage (H₂S resistance). |

|

Industrial |

Oil refinery cooling systems (Saudi Aramco), geothermal plants (Iceland). |

High-temperature resistance up to 80°C with special coatings. |

Dimensional Range

Diameter: DN80–DN2600 (3–102 inches)

Length: 6 meters (standard), customizable up to 9 meters.

Wall Thickness: Class K9/K10/K12, compliant with ISO 2531.

Sustainability & Certifications

Circular Economy: 100% recyclable, with 95% recycled iron content in production.

Carbon Footprint: 30% lower CO₂ emissions compared to steel pipes (ISO 14064 verified).

Certifications:

Water Safety: NSF/ANSI 61, WRAS, KIWA.

Quality Systems: ISO 9001, ISO 2531, GB/T 13295.

Ductile Iron Pipe – The Smart Choice for Sustainable Infrastructure!