Email Us

What is All Flanged Tee?

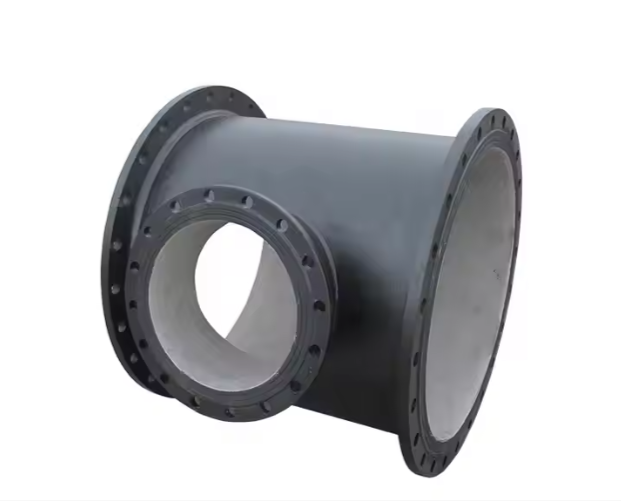

An All Flange Tee is a specially designed pipe branch connection characterized by its defining feature: all three ports—both ends of the main pipe run and the perpendicular branch outlet—are equipped with flanges. This configuration distinctly differentiates it from other tee fittings that may feature threaded, socket weld, or plain ends.

The core body of this tee is typically a standard equal or reducing tee compliant with specifications like ASME B16.9. During manufacturing, a flange—commonly a weld neck, slip-on, or socket weld type—is welded or attached to each of its three open ends. The branch outlet flange is oriented perpendicular to the flow direction within the main pipe. The primary purpose of this fully flanged design is to facilitate seamless integration into flange-based piping systems, enabling rapid and reliable assembly/disassembly via bolts and gaskets. This proves critical for applications requiring frequent equipment maintenance, system inspections (providing access points), process isolation, or future pipeline modifications and branch expansions.

Owing to its robust flanged construction, the All Flange Tee is particularly suited for demanding high-pressure, high-temperature service conditions and is often the preferred solution for large-diameter fluid transport systems. Key characteristics include:All three connections rely on bolting to mating flanges.A suitable gasket must be placed between each flange face to ensure sealing integrity.The pressure rating of the fitting is determined jointly by the flange class (e.g., 150#, 300#, 600#) and material (common grades include carbon steel A105/A350 LF2, stainless steel A182 F304/F316, alloy steels, and duplex stainless steel), while the tee body itself must comply with applicable pressure standards.Dimensions strictly adhere to relevant flange standards (e.g., ASME B16.5 or B16.47) and tee body standards (e.g., ASME B16.9).This tee is widely used in heavy industries reliant on flanged piping systems where maintenance accessibility is prioritized. Typical applications span oil and gas (upstream exploration/production, midstream transportation, downstream refining), petrochemical and chemical processing, thermal and nuclear power plants, large-scale water and wastewater treatment facilities, shipbuilding, offshore platforms, and other heavy industrial piping projects.

Despite significant advantages—ease of installation/removal, high connection strength and reliability, suitability for large diameters and harsh conditions, simplified system isolation, and standardization—All Flange Tees also present inherent drawbacks. These primarily include higher relative costs due to materials and welding for three flanges; substantially greater weight compared to non-flanged or partially flanged tees; increased space requirements for flange faces and bolt-tightening operations; and the theoretical risk of leakage at each flange joint, where sealing performance heavily depends on proper gasket selection/installation and precise bolt preload control.

As alternatives to All Flange Tees, designers may select other fitting types based on pressure class, pipe size, budget, and connection permanence requirements. Substitutes include:Threaded Tees (all ports threaded, e.g., NPT/BSPT) for low-pressure small-bore lines.Socket Weld Tees (all ports socket weld) for small-diameter high-pressure piping.Butt Weld Tees (all ends beveled for direct pipeline welding), offering the most permanent leak-proof connection but lacking disassembly capability.Combination Tees with mixed connections (e.g., flanged run ends with threaded/socket weld branch).

In summary, the All Flange Tee—defined by flanges on all three ports—serves as a critical component in flanged piping systems, enabling reliable branching, simplified maintenance, and resilience in high-pressure, high-temperature, large-diameter applications across heavy industries.

SHANDONG EPOCH EQUIPMENT CO., LTD. is a large-scale professional manufacturer in Shandong Province of China, adheres to the orientation of science and technology, environmental protection, quality and efficiency. At present, it has grown into a trans-regional and multi-industrial enterprise integrating such wide industries as design, development, production and export. Visit our website at https://www.epochpipeline.com/ to learn more about our products. For inquiries, you can reach us at sdepochwater@hotmail.com.

- Why Choose Between UPVC Pipes and HDPE Pipes?

- Why Is Ductile Iron Pipe Still the Safe Choice for Long-Life Water Networks?

- Which Pipeline Installation Machines and Tools Help Me Deliver Faster, Safer, and More Profitable Projects?

- Key points for quality inspection of ductile iron pipes

- Why do Carbon Steel Pipes keep winning tough industrial projects?

- What are the connection methods for ductile iron pipes?

About Us

Contact Us

No. 112, Jiefang Road, Lixia District, Jinan City, Shandong Province, China

Copyright © 2025 Shandong Epoch Equipment Co., Ltd. All Rights Reserved.