Email Us

What is GT Type Ductile Iron Pipe?

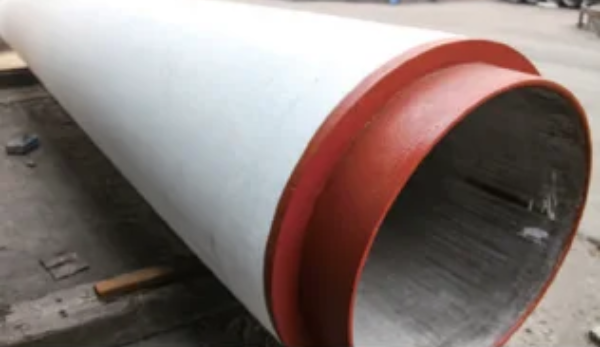

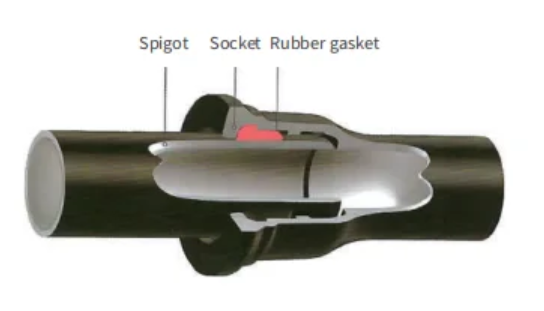

The GT Type Ductile Iron Pipe is an ISO 2531/EN 545 standardized ductile iron pipeline system, where "GT" (Gravity-Tight) denotes its core sealing mechanism. Featuring a push-on joint with wedge-shaped rubber gaskets, GT Type pipes are manufactured from high-purity iron, carbon, and silicon, treated with magnesium alloy to form a spheroidal graphite microstructure. This grants GT Type pipes the corrosion resistance of traditional cast iron combined with steel-like strength and ductility. The joint design relies on elastic compression of rubber rings for rapid installation and pressure-activated sealing, establishing GT Type as the most widely used ductile iron pipe variant in global water infrastructure.

Application ScenariosGT Type pipes excel in versatile engineering contexts:Municipal water networks: Main transmission lines, distribution branches, and supply conduits;Low-pressure systems: Irrigation channels, firefighting pipelines, and industrial water circulation (operating pressure ≤16 bar);Stable ground installations: Buried deployment in non-seismic flat or gently sloped terrain (supplemented with concrete thrust blocks);Gravity-flow and low-pressure sewage: Effluent discharge pipes in wastewater treatment plants (with cement mortar lining).

Key Advantages1. Joint Efficiency & Reliability15-second installation: Push-on joints eliminate bolts, cutting assembly time by >50%;Self-energizing seal: Internal pressure enhances gasket compression, improving leak-tightness;Flexible deflection: Allows 3°–5° joint angularity to accommodate ground settlement and installation tolerances (ISO 16134 certified for 0.3g seismic resistance).2. Superior Material PerformanceMechanical robustness: Tensile strength ≥420 MPa (3× higher than PVC), elongation ≥10% (exceeding cast iron’s 2%);Extended service life: 50–100-year corrosion resistance without cathodic protection;Optimal hydraulics: Cement mortar lining achieves Hazen-Williams coefficient C=140, minimizing pumping costs.3. Lifecycle Cost EfficiencyLower CAPEX: 20%–30% cost reduction vs. equivalent steel pipes;Near-zero OPEX: Failure rates below plastic piping systems;Century-long durability: Total ownership costs 40% lower than PVC alternatives.4. Environmental AdaptabilityDrinking water safety: Complies with NSF/ANSI 61, eliminating heavy metal leaching risks;Customized corrosion protection: Zinc-ash + bitumen/polyurethane coatings withstand soil pH 4–10.

SHANDONG EPOCH EQUIPMENT CO., LTD. is a large-scale professional manufacturer in Shandong Province of China, adheres to the orientation of science and technology, environmental protection, quality and efficiency. At present, it has grown into a trans-regional and multi-industrial enterprise integrating such wide industries as design, development, production and export. Visit our website at https://www.epochpipeline.com/ to learn more about our products. For inquiries, you can reach us at sdepochwater@hotmail.com.

- Why Choose Between UPVC Pipes and HDPE Pipes?

- Why Is Ductile Iron Pipe Still the Safe Choice for Long-Life Water Networks?

- Which Pipeline Installation Machines and Tools Help Me Deliver Faster, Safer, and More Profitable Projects?

- Key points for quality inspection of ductile iron pipes

- Why do Carbon Steel Pipes keep winning tough industrial projects?

- What are the connection methods for ductile iron pipes?

About Us

Contact Us

No. 112, Jiefang Road, Lixia District, Jinan City, Shandong Province, China

Copyright © 2025 Shandong Epoch Equipment Co., Ltd. All Rights Reserved.