Email Us

What is Flanged Resilient NRS Gate Valve with Bypass Outlet (Z45XL)?

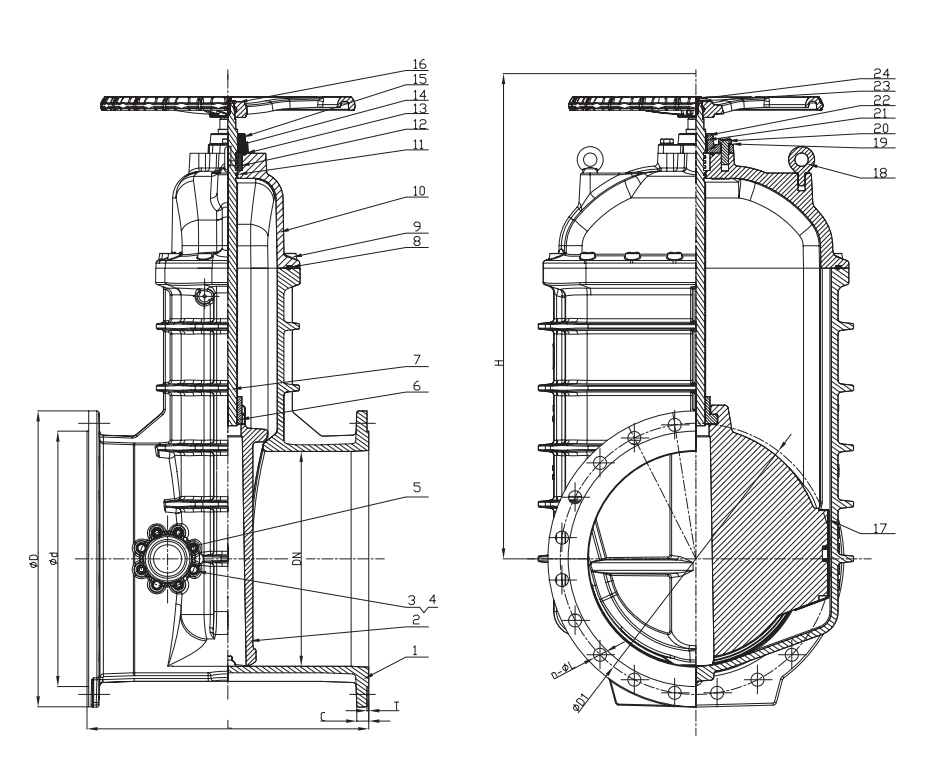

Basic Type & Core Structure:

This is a gate valve. Its core component is a disc-shaped gate/wedge that moves in a straight line perpendicular to the fluid flow direction to open (gate lifts to allow flow) or close (gate lowers to block flow). This design results in minimal flow resistance when fully open.

Key Sealing Technology - Resilient Seat:

The valve employs a resilient seat design. This means the valve's sealing ring (seat) is typically made of high-quality rubber (like EPDM, NBR) and is elastic/flexible. When the valve closes, the gate presses against the resilient seat, causing the rubber to deform and tightly conform to the gate's edge, creating a reliable seal. This design offers some tolerance for minor impurities (like silt) in the pipeline and provides excellent sealing, particularly suitable for low or medium-pressure applications.

Stem Operation Method - NRS:

NRS stands for Non-Rising Stem. When operating the valve (usually by rotating a handwheel or gearbox), the stem itself only rotates; it does NOT move axially upwards or downwards. The stem's rotary motion is converted into the gate's linear lifting/lowering movement via an internal threaded mechanism (usually a gate nut). The main advantage of this design is its minimal overhead clearance requirement; the top of the stem does not rise during opening/closing, making it ideal for space-constrained installations (like underground valve pits).

Connection Method - Flanged:

The valve's inlet and outlet ends feature flanges. Flanges are circular rims with bolt holes. During installation, bolts are used to tightly connect the valve's flanges to the corresponding mating flanges on the pipeline, with a gasket placed in between to achieve sealing. Flanged connection is one of the most common and reliable methods for pipeline valves, facilitating easy installation, removal, maintenance, and withstanding higher pressures and tensile forces.

Core Feature - With Bypass Outlet:

This is the most distinctive feature of this valve. It has an additional, smaller outlet on the valve body (typically near the inlet side or in the middle), called a bypass outlet or bleed port. This bypass port is usually equipped with a small-diameter ball valve, plug valve, or globe valve (known as the bypass valve).

Core Functions of the Bypass Outlet:Balancing Pressure Across the Main Valve: Before opening the main gate valve, especially when there is a significant pressure difference (high differential pressure) across it, the bypass valve is opened slowly first. This allows fluid from the high-pressure side to gradually flow through the bypass line into the low-pressure side, equalizing the pressure on both sides of the main gate.Reducing Operating Torque & Protecting the Valve: After pressure equalization, the force (torque) required to open the main valve is significantly reduced, making operation easier. More importantly, this prevents the risks associated with forcing the main valve open under high differential pressure, such as severe gate vibration, scoring/wear of the seat sealing surface, or even stem deformation/breakage, greatly protecting the valve and extending its service life.Pressure Relief: After closing the main gate valve, if downstream piping or equipment needs maintenance, pressure in the downstream pipeline can be safely released via the bypass valve.Minor Flow Control / Sampling: The bypass valve can also be used for small flow fluid transfer or sampling.

Operation & Indication:

The valve is typically operated via a top-mounted handwheel (smaller sizes) or gearbox (larger sizes or where easier operation is needed). Due to the NRS design, rotating the handwheel/gearbox input shaft causes the gate to lift/lower. The valve usually includes a position indicator (e.g., pointer and dial) that clearly shows whether the valve is in the open, closed, or intermediate position.

Primary Application Scenarios:

This valve is particularly suitable for applications requiring frequent operation or where high differential pressure may exist during operation. Common uses include:Water Supply Networks (Municipal, Industrial): Main pipelines, pump station outlets, zone isolation valves, especially where water hammer risk is high or main valve protection is needed.Fire Protection Systems: Fire pump discharges, main control valves, ensuring safe and reliable valve operation during emergencies.Irrigation Systems: Mainline control.Industrial Processes: Pipeline systems requiring pressure equalization to protect valves or facilitate operation.

Model Designation - Z45XL:

Z45XL is a typical model designation for this type of valve under the Chinese National Standard (GB):Z: Represents Gate Valve (Zha Fa - 闸阀).4: Represents Flanged Connection.5: Represents operation via Bevel Gear (or broadly signifies gearbox operation, distinguishing it from 3 for worm gear). In actual products, smaller sizes might use a handwheel directly, but the model may still retain this series number.XL: Typically signifies that the valve features a Resilient Seat (Xing - 弹性) and includes a Bypass Outlet (Long - 旁通). This is the key identifier distinguishing this model from a standard resilient seat gate valve (e.g., Z45X - resilient seat only, no bypass).

SHANDONG EPOCH EQUIPMENT CO., LTD. is a large-scale professional manufacturer in Shandong Province of China, adheres to the orientation of science and technology, environmental protection, quality and efficiency. At present, it has grown into a trans-regional and multi-industrial enterprise integrating such wide industries as design, development, production and export. Visit our website at https://www.epochpipeline.com/ to learn more about our products. For inquiries, you can reach us at sdepochwater@hotmail.com.

- Why Choose Between UPVC Pipes and HDPE Pipes?

- Why Is Ductile Iron Pipe Still the Safe Choice for Long-Life Water Networks?

- Which Pipeline Installation Machines and Tools Help Me Deliver Faster, Safer, and More Profitable Projects?

- Key points for quality inspection of ductile iron pipes

- Why do Carbon Steel Pipes keep winning tough industrial projects?

- What are the connection methods for ductile iron pipes?

About Us

Contact Us

No. 112, Jiefang Road, Lixia District, Jinan City, Shandong Province, China

Copyright © 2025 Shandong Epoch Equipment Co., Ltd. All Rights Reserved.