Email Us

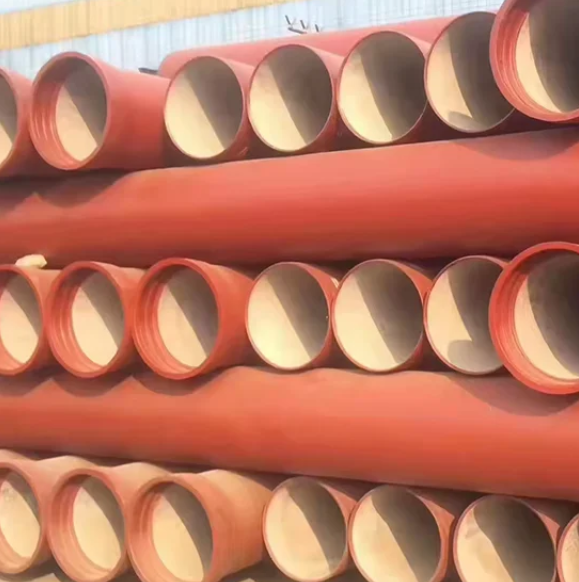

Ductile iron sewage pip

The core advantage of ductile iron sewage pipes lies in the exceptional properties of the material itself. Unlike traditional grey cast iron, ductile iron is produced through a special smelting process where elements like magnesium are added to the molten iron. This transforms the internal graphite structure from flake-shaped to spheroidal. This seemingly minor structural change brings a quantum leap in performance, endowing the material with remarkable strength, toughness, and ductility. Consequently, ductile iron sewage pipes can withstand complex underground soil pressures, surface traffic loads, and stresses generated by internal sewage flow, significantly reducing the risk of brittle fracture and providing a solid foundation for long-term, safe operation.

These significant advantages are fully demonstrated in the demanding environment of sewage transport. Sewage composition is complex, often corrosive, and pipes face constant internal moisture coupled with external exposure to soil and groundwater. Ductile iron pipe inherently possesses excellent corrosion resistance. Furthermore, the pipe's internal and external walls are typically lined with special coatings such as cement mortar, epoxy resin, or polyurethane, forming a dual protective barrier. This coating system effectively resists attack from acids, alkalis, hydrogen sulfide gas, and electrochemical corrosion. This robust corrosion resistance is key to the pipe's longevity in sewage service, with ductile iron sewage pipes having a theoretical service life potentially exceeding 50 years or even a century.

Ductile iron sewage pipe also excels in meeting the pressure and sealing requirements essential for sewage conveyance. Thanks to the material's high strength and toughness, ductile iron sewage pipe readily handles the potentially high internal pressures found in sewage networks, particularly in sections requiring pumping or significant burial depth. Simultaneously, the pipe's proven push-on joint design (typically utilizing a rubber sealing ring) ensures ease of connection and highly reliable sealing. The flexible joint design not only allows for a degree of angular deflection during installation and operation to accommodate ground settlement but also effectively prevents sewage leakage (which could pollute the environment) and groundwater infiltration (which would increase treatment loads), making this joint system a vital component for environmental protection and safe operation.

The application scope for ductile iron sewage pipe is extensive, covering virtually every segment of modern urban sewage collection and transport. Ductile iron sewage pipe is found in city trunk sewer mains, large municipal outfalls, branch collection lines in residential areas, commercial districts, and industrial parks, as well as inlet and outlet pipes for wastewater treatment plants. Ductile iron sewage pipe is particularly well-suited for critical sections demanding high pipe strength, durability, and sealing integrity, such as crossings beneath roads, railways, or rivers, or in areas with complex geology prone to subsidence. The pipe's reliable performance makes ductile iron sewage pipe a crucial backbone material in both gravity-flow (relying on gradient) and pressure-flow (relying on pumping stations) sewage systems.

Furthermore, the manufacturing and installation of ductile iron sewage pipe offer considerable convenience and economic advantages. Standardized production ensures a comprehensive range of fittings (such as straight pipes, bends, tees, reducers, etc.) and a wide size spectrum (commonly from DN80 to DN2600 or larger), meeting the needs of complex network layouts. Although the initial cost per pipe length might be higher than some alternative materials, the ductile iron sewage pipe's exceptionally long service life, very low maintenance requirements, outstanding operational reliability, and high recyclability often result in superior life-cycle cost (LCC) competitiveness. Installation of ductile iron sewage pipe is relatively mature and efficient, with proven, reliable jointing methods backed by long-term practical experience.

In summary, ductile iron sewage pipes, leveraging these pipes' inherent material strengths of high tensile strength, toughness, superior corrosion resistance, exceptional sealing performance, and joint adaptability, combined with long life and relatively economical total cost, are an indispensable and trusted key component in modern sewage collection and transport systems. Ductile iron sewage pipes play a vital role in safeguarding urban drainage security and environmental protection. The reliability and durability of ductile iron sewage pipes ensure these pipes maintain a significant position in the demanding field of sewage conveyance.

SHANDONG EPOCH EQUIPMENT CO., LTD. is a large-scale professional manufacturer in Shandong Province of China, adheres to the orientation of science and technology, environmental protection, quality and efficiency. At present, it has grown into a trans-regional and multi-industrial enterprise integrating such wide industries as design, development, production and export. Visit our website at https://www.epochpipeline.com/ to learn more about our products. For inquiries, you can reach us at sdepochwater@hotmail.com.

- Why Choose Between UPVC Pipes and HDPE Pipes?

- Why Is Ductile Iron Pipe Still the Safe Choice for Long-Life Water Networks?

- Which Pipeline Installation Machines and Tools Help Me Deliver Faster, Safer, and More Profitable Projects?

- Key points for quality inspection of ductile iron pipes

- Why do Carbon Steel Pipes keep winning tough industrial projects?

- What are the connection methods for ductile iron pipes?

About Us

Contact Us

No. 112, Jiefang Road, Lixia District, Jinan City, Shandong Province, China

Copyright © 2025 Shandong Epoch Equipment Co., Ltd. All Rights Reserved.