Email Us

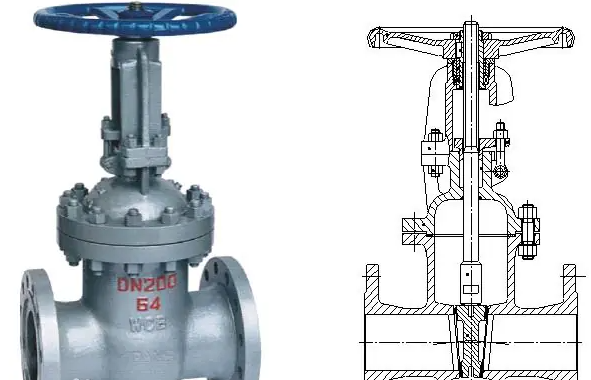

Why do gate valves always leak?

The core sealing of a gate valve relies on the tight fit between its wedge or parallel disc and the valve seats. In theory, when the disc is fully lowered, it should block the fluid passage. However, in practice, solid particles in the fluid (such as sediment, welding slag, or scale) can easily become trapped between the disc and the seat sealing surfaces. Even very small particles can prevent the disc from fully seating, leaving microscopic gaps on the sealing surface and causing leakage. This phenomenon is particularly common in pipelines with unclean fluids.

The valve stem achieves dynamic sealing through the stuffing box to prevent medium from leaking outward along the stem. The packing material (usually graphite, PTFE, etc.) experiences friction and wear as the stem moves up and down. Over time, the packing material ages, hardens, loses elasticity, or even wears away. If the gland flange isn't tightened promptly or if the compression force is uneven, the worn or aged packing cannot tightly envelop the stem, leading to seal failure and external leakage at the stem. Valves operated frequently experience faster packing wear.

The valve body is typically composed of two or more connected parts, with the connection points (like the body flange) relying on gaskets for sealing. If the gasket material is unsuitable (not resistant to medium corrosion or temperature), improperly compressed during installation, or loses compression force during service due to temperature/pressure fluctuations or bolt stress relaxation, the gasket seal fails, causing leakage at the valve body connection. Additionally, although less common, casting defects in the valve body itself (like sand holes or porosity) are potential leak points, especially under high pressure.

Gate valves are designed specifically for either fully open or fully closed positions and should not be used for flow regulation. If a gate valve remains partially open for extended periods, high-velocity flowing media directly erodes the disc sealing surface and the downstream seat sealing surface, causing localized wear or forming grooves. This erosion damage permanently compromises the flatness and finish of the sealing surfaces. Even when the valve is fully closed again, the worn areas become leakage paths.

During valve manufacturing or repair, if the sealing surfaces of the disc or seats have insufficient machining precision (lacking flatness or surface finish), or if their fit is poor (e.g., the taper angle of a wedge disc doesn't perfectly match the seat taper), then when closed, the sealing surfaces cannot form a uniform, continuous line or surface contact. Microscopic gaps inevitably remain, causing leakage. Furthermore, if the sealing surface material lacks sufficient hardness or corrosion resistance, long-term use with hard particles or corrosive media can easily cause scratches, pits, or corrosion spots, compromising sealing integrity.

During operation, especially under high temperatures, the valve body and internal components undergo thermal expansion. If materials for the disc, seats, and body have different coefficients of thermal expansion, or if thermal effects weren't adequately considered in the design, the sealing relationship that was tight under cold conditions can be disrupted at operating temperatures, leading to leakage due to inadequate sealing. Similarly, stresses in the piping system (e.g., installation stress, thermal stress) transmitted to the valve can cause slight deformation of the body or connecting flanges, affecting the concentricity of the sealing surfaces.

Rough operation (e.g., slamming the valve shut forcefully) can cause impact damage (chipping, deformation) to the disc or seat sealing surfaces. Insufficient closing torque prevents the disc from fully seating and generating the necessary sealing specific pressure, especially when particles are present or the medium has high viscosity. Opening the valve before the disc is fully lifted and subjecting it to high differential pressure can also damage sealing surfaces. Misaligned piping during installation imposes additional stress on the valve, causing body deformation or stem bending, which in turn hinders proper disc seating and sealing.

In summary: Leakage in gate valves results from a combination of multiple factors. Their inherent structure (relying on large-area planar/tapered sealing, featuring a dynamic stem seal) makes them highly sensitive to requirements for sealing surface cleanliness, machining precision, material compatibility, and operation/maintenance. Any issue—such as trapped particles, sealing surface damage (erosion, corrosion, scratches), stem packing failure, thermal expansion effects, improper operation, or installation problems—can lead to seal failure, resulting in internal leakage (at the seats) or external leakage (at the stem, body connections). Therefore, for critical shutoff applications demanding zero leakage, gate valves are often not the optimal choice; ball valves or plug valves may offer more reliable sealing performance.

SHANDONG EPOCH EQUIPMENT CO., LTD. is a large-scale professional manufacturer in Shandong Province of China, adheres to the orientation of science and technology, environmental protection, quality and efficiency. At present, it has grown into a trans-regional and multi-industrial enterprise integrating such wide industries as design, development, production and export. Visit our website at https://www.epochpipeline.com/ to learn more about our products. For inquiries, you can reach us at sdepochwater@hotmail.com.

- Why Choose Between UPVC Pipes and HDPE Pipes?

- Why Is Ductile Iron Pipe Still the Safe Choice for Long-Life Water Networks?

- Which Pipeline Installation Machines and Tools Help Me Deliver Faster, Safer, and More Profitable Projects?

- Key points for quality inspection of ductile iron pipes

- Why do Carbon Steel Pipes keep winning tough industrial projects?

- What are the connection methods for ductile iron pipes?

About Us

Contact Us

No. 112, Jiefang Road, Lixia District, Jinan City, Shandong Province, China

Copyright © 2025 Shandong Epoch Equipment Co., Ltd. All Rights Reserved.