Email Us

What is the principle of a control valve?

The core function of a control valve is to precisely regulate process parameters such as fluid flow rate, pressure, level, or temperature within a pipeline. It achieves this by altering the size of the internal flow passage cross-sectional area. Imagine a water faucet on a pipe: opening it wider increases the water flow, while closing it reduces the flow. A control valve operates similarly, but its control is far more precise and is typically operated remotely by an automated system.

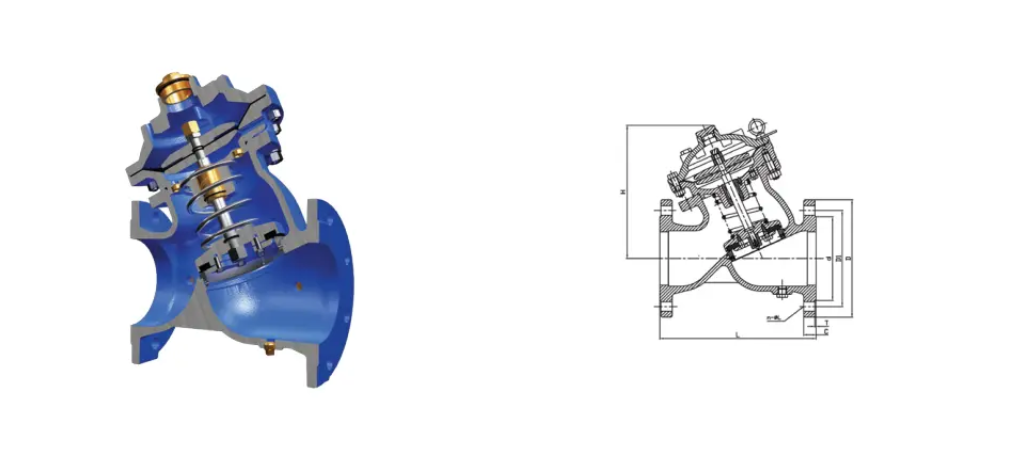

A control valve primarily consists of two key components: the control valve body assembly and the actuator. The valve body assembly includes the body itself, the trim (the throttling element such as a plug, disc, or ball), and the seat. The trim is the moving part that directly changes the flow area. The actuator is the power-providing device; it receives signal commands (typically electrical or pneumatic) from the control system and converts that signal into mechanical force (linear or rotary motion) to move the trim. Common types of actuators include pneumatic diaphragm, pneumatic piston, electric motor, or electro-hydraulic.

The core principle of its operation is based on force balance and position adjustment. The control system (such as a DCS or PLC) calculates the required control action using a specific control algorithm (like PID) based on the deviation between the actual measured process parameter (e.g., flow, pressure) and the desired value (setpoint). It then outputs a standard signal (e.g., a 4-20mA current signal or a 0.2-1.0 bar pneumatic signal) to the control valve's actuator. Upon receiving this signal, the actuator generates a corresponding thrust or torque.

The force generated by the actuator drives the valve stem, which moves the trim within the valve body (linearly or rotationally), thereby changing the opening (the flow area) between the trim and the seat. For example, when the control signal demands increased flow, the actuator pushes the trim away from the seat, increasing the valve opening and allowing more fluid to pass. Conversely, when the signal demands decreased flow, the actuator pulls the trim towards the seat, reducing the opening and restricting fluid flow.

Through this continuous or step-wise adjustment of the opening, the control valve dynamically alters the fluid resistance or flow capacity through the valve. The change in flow area directly impacts the fluid flow rate, which in turn affects the controlled process parameter (e.g., increasing flow typically raises downstream pressure or vessel level). The new valve position state influences the process; sensors measure the actual parameter again and feed it back to the controller. The controller calculates a new output signal based on this, forming a closed-loop control system. This system continuously maintains the process parameter precisely near the required setpoint. Therefore, the control valve is an indispensable final control element for achieving automation in industrial processes.

SHANDONG EPOCH EQUIPMENT CO., LTD. is a large-scale professional manufacturer in Shandong Province of China, adheres to the orientation of science and technology, environmental protection, quality and efficiency. At present, it has grown into a trans-regional and multi-industrial enterprise integrating such wide industries as design, development, production and export. Visit our website at https://www.epochpipeline.com/ to learn more about our products. For inquiries, you can reach us at sdepochwater@hotmail.com.

- Why Choose Between UPVC Pipes and HDPE Pipes?

- Why Is Ductile Iron Pipe Still the Safe Choice for Long-Life Water Networks?

- Which Pipeline Installation Machines and Tools Help Me Deliver Faster, Safer, and More Profitable Projects?

- Key points for quality inspection of ductile iron pipes

- Why do Carbon Steel Pipes keep winning tough industrial projects?

- What are the connection methods for ductile iron pipes?

About Us

Contact Us

No. 112, Jiefang Road, Lixia District, Jinan City, Shandong Province, China

Copyright © 2025 Shandong Epoch Equipment Co., Ltd. All Rights Reserved.