Email Us

The structure and working principle of the butterfly valve

90-degree rotation, effortless flow control mastery — Butterfly Valves: Optimizing efficiency and cost for large-diameter pipeline operations!

1.Overall Overview:

A butterfly valve is a structurally simple and quick-operating valve primarily used to control the flow of fluids (such as water, gas, or slurries) in pipelines. Its core function is to open, close, or regulate the flow passage by rotating a disc (butterfly disc) within the pipe.

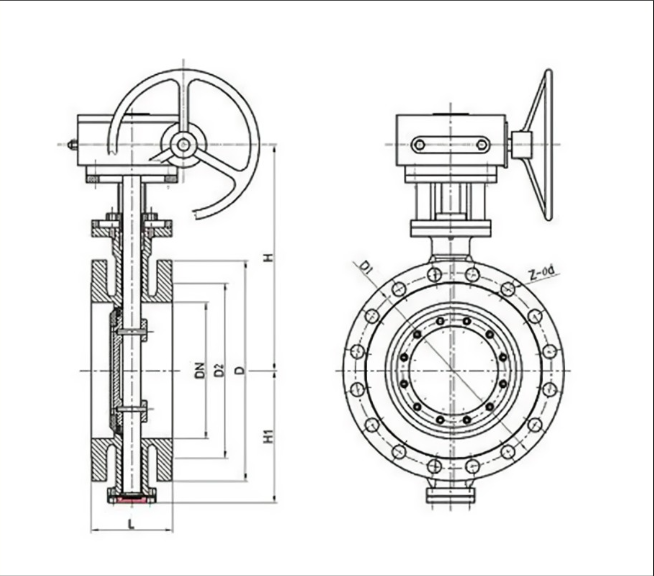

2.Key Components - Valve Body and Disc:

The main body of the butterfly valve is the valve body, a short cylindrical housing connected to the pipeline at both ends, forming the fluid passage. Positioned centrally within the valve body passage is the core component – the disc. This is a disc-shaped structure whose design (concentric or eccentric) and material significantly impact the valve's performance.

3.Key Components - Stem and Actuation:

A stem passes through the center or an eccentric point of the disc and extends outside the valve body. This shaft is responsible for transmitting the rotational force (torque) generated by the external operating mechanism (such as a lever, handwheel, or automatic actuator) to the disc, driving its rotation.

4.Key Components - Sealing (Seat and Seals):

To achieve sealing when closed, an annular seat is installed on the inner wall of the valve body (or on the disc edge in triple-offset designs). When the disc closes, its edge presses tightly against this seat. Seat materials can be elastomers (soft seat, e.g., rubber, PTFE, offering good sealing) or metal (hard seat, resistant to high temperature and pressure). Additionally, seals (such as packing or O-rings) are located where the stem exits the valve body, preventing media leakage along the stem.

5.Working Principle - Opening Process:

When the valve needs to be opened, the operating mechanism (manual or automatic) rotates the stem. The stem causes the disc to rotate around its axis, moving from a position perpendicular to the pipeline axis (90 degrees, closed state) towards a position parallel to it (0 degrees). As the disc rotates, its obstruction to the fluid decreases, the flow passage gradually opens, and fluid flows smoothly through. The rotation angle allows precise control of the flow rate.

6.Working Principle - Closing Process:

When the valve needs to be closed, the operating mechanism rotates the stem in the opposite direction. The disc begins rotating from its position parallel to the pipeline, progressively blocking the flow path. Upon rotating approximately 90 degrees to reach the perpendicular position, the disc's edge presses firmly against the seat. Through this compression (relying on elastic deformation for soft seats, or precise conical taper contact for hard seats), a complete sealing ring is formed between the disc edge and the seat, completely blocking fluid flow.

7.Main Advantages:

The primary advantages of butterfly valves lie in their compact structure, light weight, and short face-to-face dimensions (saving space), simple and quick operation (typically requiring only a 90-degree rotation for open/close), low fluid resistance (especially when fully open), low operating torque, and significant cost advantages in large-diameter pipelines.

8.Main Disadvantages and Considerations:

Disadvantages of butterfly valves include their sealing pressure capability typically being lower than gate or globe valves (especially soft-seated types), the disc always being present in the flow path causing some pressure loss, being less suitable for severe throttling applications (which may cause vibration or erosion), and the sensitivity of soft-seat materials to extreme temperatures.

9.Typical Applications:

Leveraging these advantages, butterfly valves are widely applied in medium-to-large diameter scenarios demanding quick operation, space constraints, or cost sensitivity. Common applications include: water supply and drainage systems (potable water, wastewater), HVAC (Heating, Ventilation, and Air Conditioning) systems, fire protection systems, cooling water in the power industry, petrochemical industry (for low-pressure, ambient-temperature media), food and pharmaceutical industries (sanitary-grade valves), and slurry handling.

SHANDONG EPOCH EQUIPMENT CO., LTD. is a large-scale professional manufacturer in Shandong Province of China, adheres to the orientation of science and technology, environmental protection, quality and efficiency. At present, it has grown into a trans-regional and multi-industrial enterprise integrating such wide industries as design, development, production and export. Visit our website at https://www.epochpipeline.com/ to learn more about our products. For inquiries, you can reach us at sdepochwater@hotmail.com.

- Why Is Ductile Iron Pipe Still the Safe Choice for Long-Life Water Networks?

- Which Pipeline Installation Machines and Tools Help Me Deliver Faster, Safer, and More Profitable Projects?

- Key points for quality inspection of ductile iron pipes

- Why do Carbon Steel Pipes keep winning tough industrial projects?

- What are the connection methods for ductile iron pipes?

- The Origin of the Butterfly Valve's Name

About Us

Contact Us

No. 112, Jiefang Road, Lixia District, Jinan City, Shandong Province, China

Copyright © 2025 Shandong Epoch Equipment Co., Ltd. All Rights Reserved.