Email Us

The differences in structure between Globle valves and Gate valves

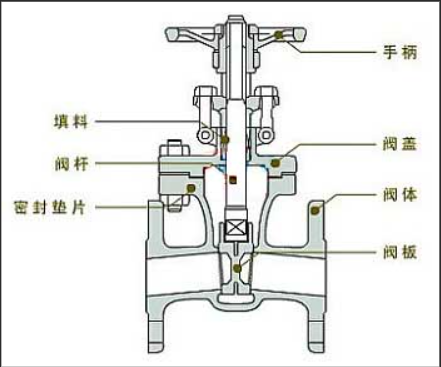

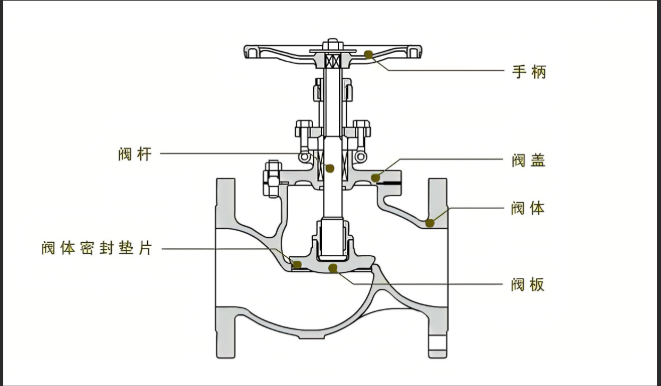

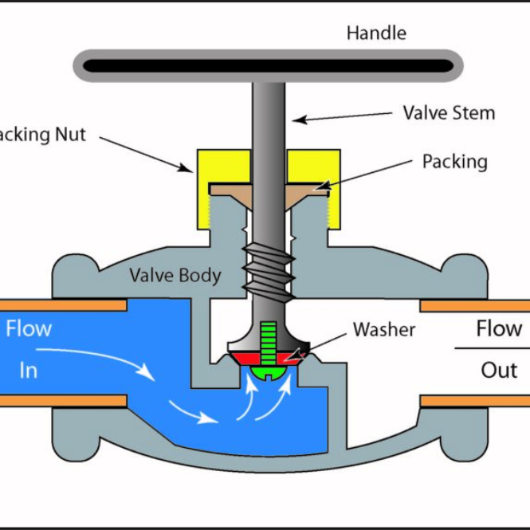

1. Fundamental Difference in Closure MechanismThe core moving part of a gate valve is a gate slab, typically wedge-shaped (though parallel or flexible designs exist). This slab moves perpendicular to the fluid flow direction—imagine a vertical guillotine that rises to allow straight-through flow or drops to block the passage. In contrast, a globe valve operates via a disc (or plug/poppet), often disc-shaped, conical, or needle-like. Its movement is parallel to the flow direction, functioning like a piston that screws downward into the valve seat to close or retracts upward to open.

2. Internal Flow Path DesignThis distinction directly impacts valve shape and fluid resistance. Gate valves feature a straight, symmetrical flow path. When fully open, the gate retracts into a chamber above the bore, allowing fluid to pass unimpeded like a straight pipe section, resulting in negligible flow resistance. Globe valves, however, force fluid through a bent, "S" or "Z"-shaped passage. Flow direction changes sharply (usually downward then upward, or vice versa), with the bore constricting at the valve seat. This design inherently creates significant flow resistance and pressure drop.

3. Body Profile and Flow Direction RequirementsFlow path design dictates body appearance. Gate valve bodies are symmetrical and cylindrical, with flanges aligned axially. Their straight, bidirectional flow path imposes no flow direction requirements—fluid performs identically in either direction when fully open. Globe valve bodies are asymmetrical, displaying a distinct central bulge or protrusion to accommodate the curved flow path. Critically, they enforce strict flow direction rules: most follow "LIOH" (Liquid In Below Disc, Out Above Disc). The body is marked with a flow arrow; reverse installation causes sealing failure, high operating torque, or damage.

4. Stem Travel and Valve HeightClosure mechanism affects stem travel and overall dimensions. To fully open, a gate valve must lift its gate above the full bore diameter—a long stroke for large valves. Rising-stem designs show visible stem extension; non-rising stems conceal internal travel. Globe valves need only ~25% of seat bore lift for full opening (as flow area expands rapidly after initial lift). Thus, stem travel is shorter. However, their "S"-path design makes globe valve bodies taller (from inlet centerline to bonnet top) than gate valves of equal size, appearing "bulkier".

5. Sealing Structure and InterfaceSealing methods and surfaces differ significantly. Gate valves seal through broad contact areas between both sides of the gate and corresponding body seats. Wedge gates achieve closure via mechanical wedging; parallel gates use forced contact against seats. This creates large sealing interfaces. Globe valves seal along a concentrated contact line between the disc edge (conical/ spherical) and a ring-shaped valve seat. Downward force from the stem presses the disc into the seat, enabling line contact or narrow-face sealing with minimal surface area.

SHANDONG EPOCH EQUIPMENT CO., LTD. is a large-scale professional manufacturer in Shandong Province of China, adheres to the orientation of science and technology, environmental protection, quality and efficiency. At present, it has grown into a trans-regional and multi-industrial enterprise integrating such wide industries as design, development, production and export. Visit our website at https://www.epochpipeline.com/ to learn more about our products. For inquiries, you can reach us at sdepochwater@hotmail.com.

- Why Choose Between UPVC Pipes and HDPE Pipes?

- Why Is Ductile Iron Pipe Still the Safe Choice for Long-Life Water Networks?

- Which Pipeline Installation Machines and Tools Help Me Deliver Faster, Safer, and More Profitable Projects?

- Key points for quality inspection of ductile iron pipes

- Why do Carbon Steel Pipes keep winning tough industrial projects?

- What are the connection methods for ductile iron pipes?

About Us

Contact Us

No. 112, Jiefang Road, Lixia District, Jinan City, Shandong Province, China

Copyright © 2025 Shandong Epoch Equipment Co., Ltd. All Rights Reserved.