Email Us

The characteristics and classification of gate valves

A gate valve, also known as a gate plate valve, is a valve whose opening and closing part is a gate plate, and which is driven by a valve stem to move the gate plate up and down.

The characteristics of gate valves

1) Advantages of gate valves: Low fluid flow resistance; The torque required for opening and closing is small. The flow direction of the medium is unrestricted. There is no water hammer phenomenon when opening and closing. The shape structure is relatively simple, and the manufacturing process is better.

2) Disadvantages of gate valves: They have relatively large external dimensions and installation heights, and require a considerable installation space. During the opening and closing process, there is relative friction on the sealing surface, resulting in significant wear. Even at high temperatures, it is prone to scratches. Gate valves usually have two sealing surfaces, which adds some difficulties to processing, grinding and maintenance.

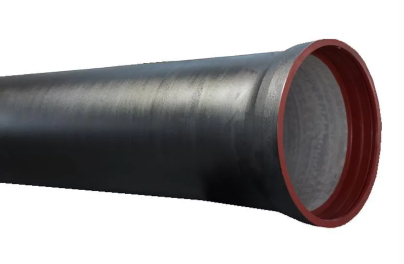

Gate valves have a wide range of applications. It is usually used for water supply pipelines with a nominal diameter of DN50 or more.

Classification of gate valves

Gate valves can be classified by connection methods into threaded gate valves, flanged gate valves and welded gate valves. According to structural features, they can be divided into parallel gate plates and wedge gate plates. Based on the structure of the valve stem, they can be classified into distinct stem (lifting stem) gate valves and concealed stem (rotating stem) gate valves.

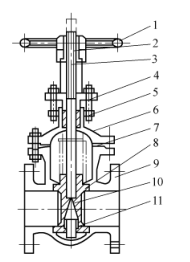

1) Open stem parallel double gate valve: The open stem parallel double gate valve is shown in Figure 1. Its gate is composed of two symmetrical and parallel discs. When the gate descends, the top wedge placed at the bottom of the gate causes the two gates to expand outward and tightly press against the valve seat, thus closing the valve tightly. When the gate rises, the wedge disengages from the disc. Once the disc rises to a certain height, the wedge is lifted by the protrusions on the disc and rises along with the gate. This valve has a simple structure. The processing, grinding and maintenance of its sealing surface are all simpler than those of the wedge gate valve. However, its sealing performance is relatively poor. It is suitable for media with a pressure not exceeding 1.0MPa and a temperature not exceeding 200℃.

Figure 1: Rising stem parallel double gate valve

1. Handwheel 2- valve stem nut 3- valve stem 4 - packing gland 5 - packing 6 - valve cover

7 - Gasket 8 - Sealing ring 9- Valve body 10- Gate 11 - Top wedge

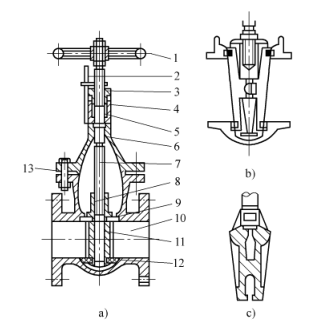

2) Concealed stem wedge gate valve: As shown in Figure 2, the sealing surface of this valve is inclined and forms an Angle. The higher the medium temperature, the larger the Angle. Wedge gate plates are classified into single gate plates, double gate plates and elastic gate plates, as shown in Figures 2a, b and c respectively. The processing, grinding and maintenance of wedge gate plates are more complicated than those of parallel gate plates, but they have better sealing performance.

Figure 2 Concealed stem wedge gate valve

a) Wedge single gate plate b) Wedge double gate plate c) Wedge elastic gate plate

1. Handwheel 2. Indicator 3. Cover 4. Stuffing box 5. Packing 6. Valve cover

7- Valve stem 8 - Valve stem nut 9, 12 - Sealing Ring 10 - Valve body 11 - Gate Plate 13 - Gasket

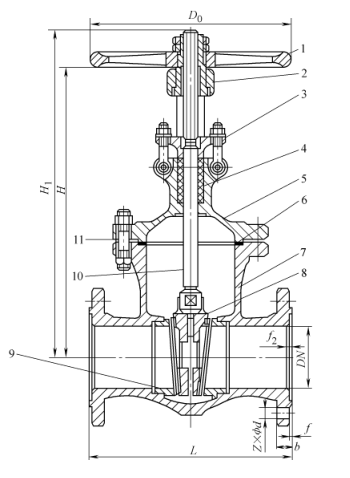

The elastic gate valve is shown in Figure 3. It has the advantages of simple structure and reliable use, and can produce a small elastic deformation, which increases the tightness of closing.

Figure 3 Elastic gate valve

1. Handwheel 2- valve stem nut 3 - packing gland 4 - packing 5 - valve cover 6 - gasket

7- Valve body 8 Gate Plate 9 - Sealing Ring 10 - Valve Stem 11 - Connecting bolt

In a rising stem gate valve, the thread of the valve stem fits with a sleeve nut equipped with a handwheel. The lower end of the valve stem has a square head, which is embedded in the gate plate. When the handwheel is turned, the valve stem and the gate plate move up and down. When opening, the valve stem extends out of the handwheel. The advantage is that the opening degree of the valve can be judged from the extended length of the valve stem, and the valve stem does not come into direct contact with the conveyed medium. The drawback is that the valve has a large opening height, and the installation site must have sufficient space for the valve stem to extend outward. When installing on site, be sure to pay attention to this point. The external thread of the valve stem of the concealed stem gate valve fits with the internal thread embedded in the valve. Therefore, when the handwheel is turned, the valve stem rotates, causing the gate inside the valve to move up and down, but the valve stem cannot move up and down. The concealed stem gate valve takes up less space during installation. The conveyed medium comes into direct contact with the valve stem, and the opening degree of the valve cannot be judged through the valve stem. Whether it is a rising stem gate valve or a non-rising stem gate valve, the gate valve must be installed horizontally. The valve stem should be vertically upward and not inclined. It is strictly prohibited to install the valve stem downward.

- Why Choose Between UPVC Pipes and HDPE Pipes?

- Why Is Ductile Iron Pipe Still the Safe Choice for Long-Life Water Networks?

- Which Pipeline Installation Machines and Tools Help Me Deliver Faster, Safer, and More Profitable Projects?

- Key points for quality inspection of ductile iron pipes

- Why do Carbon Steel Pipes keep winning tough industrial projects?

- What are the connection methods for ductile iron pipes?

About Us

Contact Us

No. 112, Jiefang Road, Lixia District, Jinan City, Shandong Province, China

Copyright © 2025 Shandong Epoch Equipment Co., Ltd. All Rights Reserved.