Email Us

Ductile Iron Pipe as a Common Material in Water Supply and Drainage Systems: Where Anti-Corrosion Linings Are Critical, What Are Its Core Strengths and How to Select the Appropriate Type?

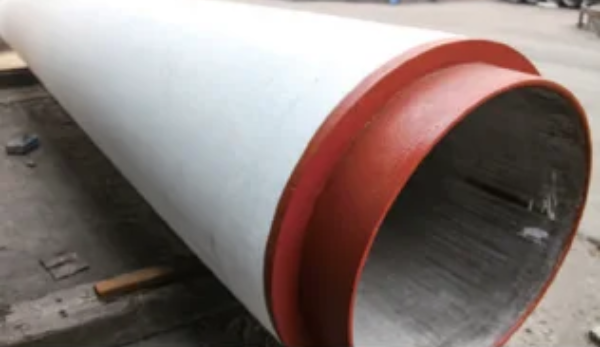

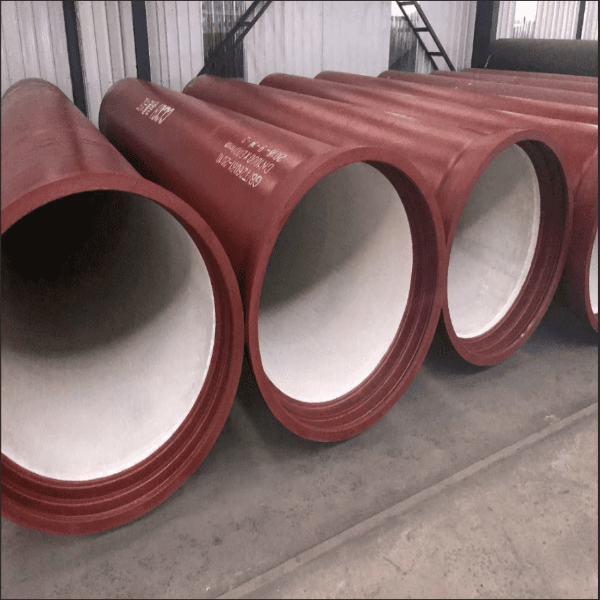

Ductile Iron Pipe as a Common Material in Water Supply and Drainage Systems: The core strengths of ductile iron pipe lie in the dual protection of the anti-corrosion lining + external coating, with the lining being more critical as it is in direct contact with the water quality. The mainstream linings used for ductile iron pipe primarily include the following: Cement Mortar Lining (CML) and epoxy resin coating, which together account for over 90% of global usage.Our company employs the centrifugal spraying process for cement mortar lining application. The cement mortar layer provides a highly alkaline environment (pH>12), forming a passivation protective film on the steel pipe surface. This effectively prevents electrochemical corrosion, stabilizes the water's pH value, reduces the "red water" phenomenon (iron leaching), and improves taste (making the water taste "sweeter"). Cement mortar lining is most widely applicable for municipal drinking water transmission networks, raw water conveyance, etc.

Epoxy resin lining significantly reduces fluid flow resistance (offering superior hydraulic performance compared to cement mortar), enabling effective savings in pumping energy consumption. Furthermore, epoxy resin lining possesses excellent chemical corrosion resistance, providing strong resistance against various acids, alkalis, salts, and solvents. The smooth and dense internal surface effectively blocks ion penetration, delivering outstanding anti-corrosion performance; it is also resistant to scaling and easy to clean. Epoxy resin lining is suitable for applications demanding high hydraulic efficiency, chemical corrosion resistance, and abrasion resistance, such as: industrial water/wastewater pipelines, seawater desalination, water/sewage containing corrosive components, main water transmission lines requiring high flow velocity and low energy consumption, the food and beverage industry, and situations requiring extremely high hygiene standards.Polyurethane lining offers good flexibility, impact resistance, and abrasion resistance. Polyurethane lining is mainly used for conveying highly abrasive media, such as ore slurry, ash slurry, and water/sewage containing large amounts of grit. Polyurethane lining is less widely used than epoxy resin in clean water applications.

The key factors in selecting the anti-corrosion lining for ductile iron pipe include eight critical considerations: the conveyed medium, water quality requirements, hydraulic requirements, abrasion resistance requirements, cost budget, design life and maintenance requirements, installation and operating environment, and relevant standards and specifications. In summary, cement mortar lining (CML) represents an economical, reliable, and versatile choice, particularly well-suited for standard municipal potable water distribution networks. Epoxy resin lining demonstrates exceptional performance in hydraulic efficiency, chemical corrosion resistance, abrasion resistance, and hygiene, making it the mainstream choice for high-performance applications demanding superior characteristics. Polyurethane lining offers a significant advantage in applications requiring extreme abrasion resistance.

SHANDONG EPOCH EQUIPMENT CO., LTD. is a large-scale professional manufacturer in Shandong Province of China, adheres to the orientation of science and technology, environmental protection, quality and efficiency. At present, it has grown into a trans-regional and multi-industrial enterprise integrating such wide industries as design, development, production and export. Visit our website at https://www.epochpipeline.com/ to learn more about our products. For inquiries, you can reach us at sdepochwater@hotmail.com.epochpipeline@hotmail.com

- Why Choose Between UPVC Pipes and HDPE Pipes?

- Why Is Ductile Iron Pipe Still the Safe Choice for Long-Life Water Networks?

- Which Pipeline Installation Machines and Tools Help Me Deliver Faster, Safer, and More Profitable Projects?

- Key points for quality inspection of ductile iron pipes

- Why do Carbon Steel Pipes keep winning tough industrial projects?

- What are the connection methods for ductile iron pipes?

About Us

Contact Us

No. 112, Jiefang Road, Lixia District, Jinan City, Shandong Province, China

Copyright © 2025 Shandong Epoch Equipment Co., Ltd. All Rights Reserved.