Email Us

What is all socket tee?

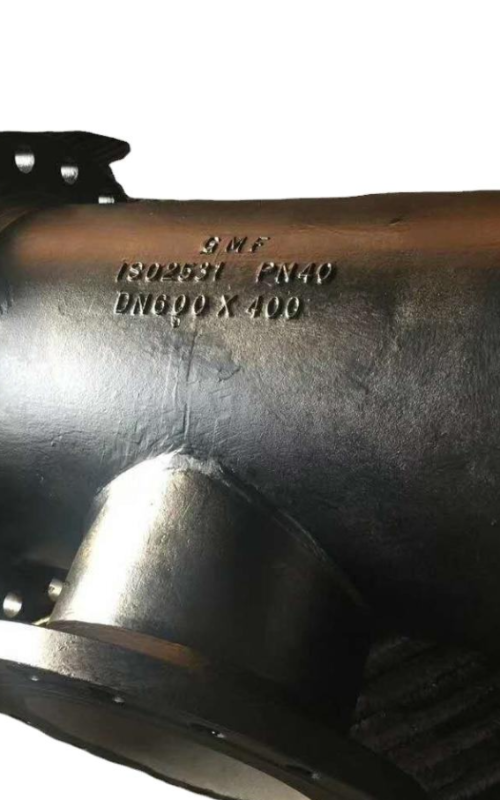

The All Socket Tee is a branch pipe fitting featuring socket-type connections on all three ports, engineered specifically for creating permanent, leak-tight 90° branch systems. Its core structure comprises precision-machined cylindrical socket cavities, where the three ports (one main run inlet and two branch outlets) seamlessly accept mating pipes through diameter-matched recesses. Unlike conventional threaded or flanged tees, this design eliminates mechanical fasteners, instead achieving monolithic integration via metallurgical welding (for metallic systems) or molecular solvent fusion (for thermoplastic systems)—employing socket welding or brazing for metal pipes, while thermoplastics like PVC/CPVC undergo chemical interfacial dissolution. This approach eradicates stress concentration at thread roots and sealing failures inherent in flanged joints, delivering four critical advantages:

Zero-Leak Reliability: Weld/solvent-bonded interfaces create gap-free seals capable of withstanding extreme conditions (>1,000 psi/6.89 MPa for metals; up to 315 psi/2.17 MPa for engineered plastics);

Structural Superiority: Uniform stress distribution resists vibration, water hammer, and thermal cycling fatigue (-196°C to 300°C);

Fluidic Efficiency: Smooth bore eliminates turbulent dead zones, reducing pressure drop by ≈15%* (*vs. threaded tees of equivalent size);

Corrosion Mitigation: Groove/crevice-free design prevents corrosive media entrapment, extending service life beyond 25 years.

This fitting serves as a foundational component for high-risk, high-pressure, and high-purity systems, with flagship applications including: hydrofluoric acid transfer lines in chemical processing (Hastelloy® construction), nuclear secondary coolant loops (316L stainless steel), semiconductor ultrapure water distribution (PVDF polymer), and fire sprinkler networks (galvanized carbon steel). Material selection strictly adheres to international standards: metallic units comply with ASME B16.11 pressure ratings, while polymer fittings meet ASTM D2467 chemical compatibility requirements—ensuring performance stability in acidic media (pH 0-14), steam service (≤300°C), and radiation environments.

SHANDONG EPOCH EQUIPMENT CO., LTD. is a large-scale professional manufacturer in Shandong Province of China, adheres to the orientation of science and technology, environmental protection, quality and efficiency. At present, it has grown into a trans-regional and multi-industrial enterprise integrating such wide industries as design, development, production and export. Visit our website at https://www.epochpipeline.com/ to learn more about our products. For inquiries, you can reach us at sdepochwater@hotmail.com.

- Why Choose Between UPVC Pipes and HDPE Pipes?

- Why Is Ductile Iron Pipe Still the Safe Choice for Long-Life Water Networks?

- Which Pipeline Installation Machines and Tools Help Me Deliver Faster, Safer, and More Profitable Projects?

- Key points for quality inspection of ductile iron pipes

- Why do Carbon Steel Pipes keep winning tough industrial projects?

- What are the connection methods for ductile iron pipes?

About Us

Contact Us

No. 112, Jiefang Road, Lixia District, Jinan City, Shandong Province, China

Copyright © 2025 Shandong Epoch Equipment Co., Ltd. All Rights Reserved.