Email Us

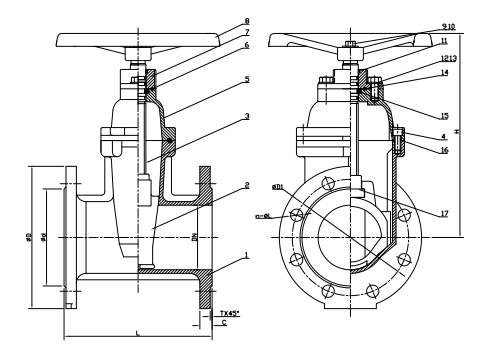

Flanged Resilient NRS Gate Valve

The Flanged Resilient Non-Rising Stem (NRS) Gate Valve is a shut-off valve with flanged connections and a non-ascending stem. Its core design features a rubber-coated wedge gate (Resilient Seat) and a non-rising stem mechanism. Rotating the handwheel drives the stem nut to move the gate vertically, sealing or opening the pipeline. Compliant with BS 5163/EN 1074 standards (pressure ratings PN10/16), the valve combines the strength of a metal body with zero-leakage elastic sealing.

Application ScenariosSpace-constrained installations:

Underground valve chambers and narrow pipe galleries (NRS design saves vertical space);Building fire protection pipeline interlayers;Low-to-medium pressure fluid control:Shutoff in municipal water supply mains;Industrial cooling water systems (withstands ≤80°C/176°F);Fire pump station inlets/outlets (UL/FM certified models);Corrosive environments:Wastewater treatment plants (EPDM seals resist weak acids/alkalis);Coastal pipelines (full epoxy coating for corrosion protection).

Core Advantages1. Sealing ReliabilityDual-seal structure: Rubber seat + metal wedge compression achieves EN 12266 Class A sealing (leakage ≤0.01%);Automatic wear compensation: Elastic seat fills micro-deformations, extending service life to 200,000 cycles.2. Space Efficiency & Low MaintenanceImpact-resistant NRS design: Fully enclosed stem prevents external damage (60% fewer failures vs. rising-stem valves);Maintenance-free operation: Self-lubricating bearings + IP68-rated stem seal (zero maintenance for 10 years).3. Engineering AdaptabilityInterchangeable flanges: ISO 5211 flanges compatible with GB/ANSI/DIN pipelines;Low flow resistance: Full-bore design (DN≥80) reduces head loss by ≥30%;Emergency shutoff: 90° handwheel rotation enables rapid closure (≤3-second response).

Industry ApplicationsSingapore PUB Water Upgrade: DN300 valves replaced aging cast steel gates (leakage reduced to 0.001%);Dubai Palm Island Fire System: NRS valves passed ISO 9227 salt-spray testing (2,000 hours);China’s Xiong'an New Area Utility Tunnel: Integrated torque sensors enable remote operation monitoring.Note: Select seat materials (EPDM/NBR/VITON) based on fluid temperature/chemical compatibility.

SHANDONG EPOCH EQUIPMENT CO., LTD. is a large-scale professional manufacturer in Shandong Province of China, adheres to the orientation of science and technology, environmental protection, quality and efficiency. At present, it has grown into a trans-regional and multi-industrial enterprise integrating such wide industries as design, development, production and export. Visit our website at https://www.epochpipeline.com/ to learn more about our products. For inquiries, you can reach us at sdepochwater@hotmail.com.

- Why Choose Between UPVC Pipes and HDPE Pipes?

- Why Is Ductile Iron Pipe Still the Safe Choice for Long-Life Water Networks?

- Which Pipeline Installation Machines and Tools Help Me Deliver Faster, Safer, and More Profitable Projects?

- Key points for quality inspection of ductile iron pipes

- Why do Carbon Steel Pipes keep winning tough industrial projects?

- What are the connection methods for ductile iron pipes?

About Us

Contact Us

No. 112, Jiefang Road, Lixia District, Jinan City, Shandong Province, China

Copyright © 2025 Shandong Epoch Equipment Co., Ltd. All Rights Reserved.