Email Us

What is T-joint Ductile Iron Pipe?

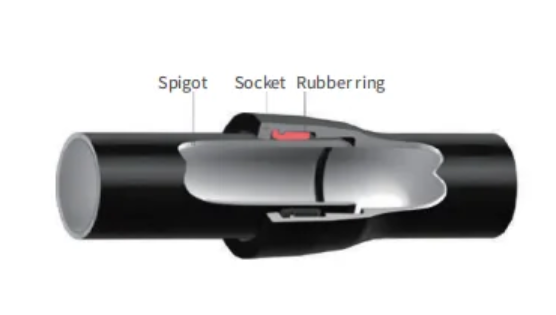

The T-Joint ductile iron pipe (also known as Mechanical Flanged Joint Pipe) is a ductile iron piping system featuring bolted flanged sockets, where the "T" designation refers to the T-shaped structural profile of the joint. Manufactured from ductile iron (tensile strength ≥420 MPa, elongation ≥10%), the T-joint comprises a socket flange, spigot flange, rubber sealing ring, and bolt assembly. The T-joint achieves rigid connections and high-pressure sealing through axial bolt compression. Compared to push-on joints (GT Type), the T-joint delivers superior structural integrity and displacement resistance, complying with ISO 2531/EN 545 and GB/T 13295 standards.

Application ScenariosT-joint pipes are engineered for high-pressure, high-vibration, frequently disassembled, or high-reliability applications:High-pressure water transmission systems: Main lines and pump station inlet/outlet pipes (working pressure ≥16 bar);Industrial piping networks: Power plant cooling water, chemical process pipelines (pressure rating up to PN25/PN40);Seismic zones: Buried or above-ground installations in earthquake-prone or geologically unstable areas (ISO 16134 certified);Maintenance-intensive nodes: Valve chambers, pipe bridge connections requiring periodic disassembly;Special conditions: River crossings or high-fill areas with external impact risks.

Core Advantages1. High-Pressure Sealing & Structural RigidityBolted mechanical locking: The T-joint withstands continuous internal pressure ≥2.5 MPa (1.6× higher than GT-type joints);Zero axial displacement: Bolt preload eliminates pipe separation risks on steep slopes/thrust points;Vibration/shock resistance: Rigid structure withstands water hammer, seismic loads, and heavy traffic (0.5g ground acceleration tolerance).2. Engineering Flexibility & SafetyDetachable design: Segment-specific maintenance via bolt removal reduces upkeep costs by >50%;Precise alignment control: Flange planes permit ±0.5° angular correction for complex installations;Leak-free guarantee: Three-stage sealing (gasket + metal contact + bolt preload) ensures 100% zero leakage.3. Full-Scenario AdaptabilityMaterial performance redundancy: The T-joint pipe body provides 40% pressure safety margin over operational requirements;Dual corrosion protection: Standard cement mortar lining + zinc/epoxy coating enables ≥100-year service life;Cross-media compatibility: EN 598 certified for sewage, seawater, and mildly corrosive industrial fluids.

SHANDONG EPOCH EQUIPMENT CO., LTD. is a large-scale professional manufacturer in Shandong Province of China, adheres to the orientation of science and technology, environmental protection, quality and efficiency. At present, it has grown into a trans-regional and multi-industrial enterprise integrating such wide industries as design, development, production and export. Visit our website at https://www.epochpipeline.com/ to learn more about our products. For inquiries, you can reach us at sdepochwater@hotmail.com.

- Why Choose Between UPVC Pipes and HDPE Pipes?

- Why Is Ductile Iron Pipe Still the Safe Choice for Long-Life Water Networks?

- Which Pipeline Installation Machines and Tools Help Me Deliver Faster, Safer, and More Profitable Projects?

- Key points for quality inspection of ductile iron pipes

- Why do Carbon Steel Pipes keep winning tough industrial projects?

- What are the connection methods for ductile iron pipes?

About Us

Contact Us

No. 112, Jiefang Road, Lixia District, Jinan City, Shandong Province, China

Copyright © 2025 Shandong Epoch Equipment Co., Ltd. All Rights Reserved.