Email Us

How are rubber flexible joints manufactured and what processes do they go through?

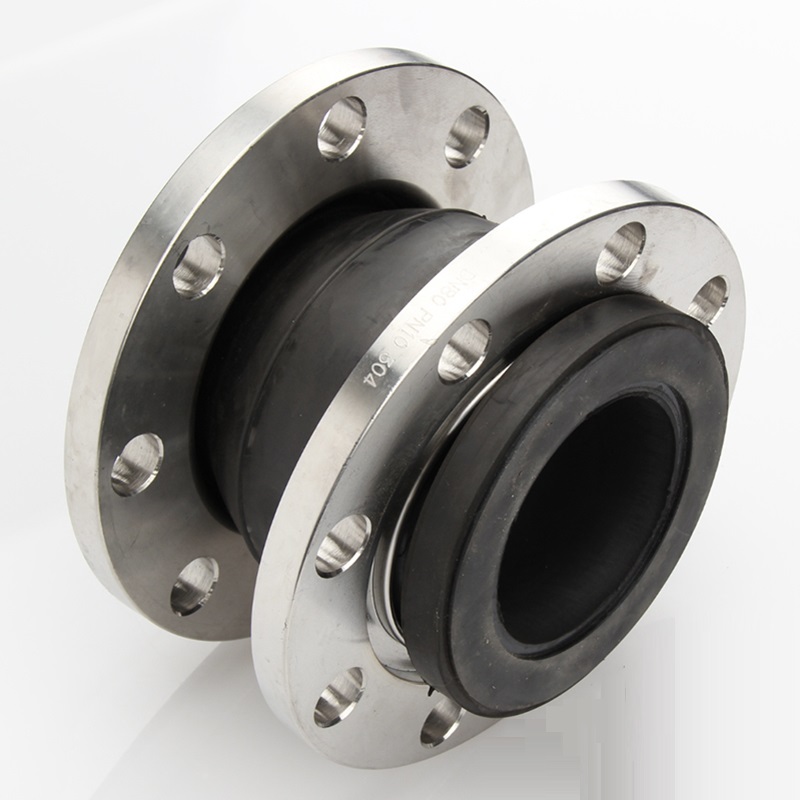

To make rubber flexible joints is no easy task. It requires going through several processing procedures to be completed. Rubber flexible joints are devices made of rubber and other materials, which can effectively reduce shock and noise. They have strong shock absorption capacity and significant noise reduction effects. Rubber flexible joints can be used wherever shock absorption is needed. So, what processing procedures are involved in the production and shaping of rubber flexible joints? Now let's get to know each other together.

1. Rubber compounding

The preparation of rubber flexible joint compound is the same as that of ordinary rubber product compound. First, the raw rubber needs to be fully plasticized to make it have appropriate plasticity and uniformity. With the increase of plasticizing time, the rubber loss coefficient decreases and its dependence on amplitude reduces. The key during mixing is to ensure that the compounding agents are evenly dispersed. If the rubber compound is not mixed evenly, it will cause fluctuations in the stiffness of the shock absorber. Due to the uneven hardness inside the rubber, stress concentration will occur, thereby shortening the service life of the shock absorber.

2. Surface treatment and bonding of metal parts

The vast majority of rubber flexible joints contain metal parts. Before the metal parts are combined with rubber, their surfaces must be treated; otherwise, it will affect their bonding strength. There are many surface treatment methods for metal parts. The commonly used one is sandblasting, followed by cleaning with solvents, drying and then applying glue. The commonly used adhesive at present is chemlok, which has a very reliable bonding strength.

3. Sulfation

The common vulcanization methods for rubber flexible joints include compression vulcanization, mold transfer vulcanization and injection vulcanization. The common compression vulcanization process and equipment are relatively simple. Heat is transferred from the upper and lower pressure surfaces to the metal mold and rubber. This method is particularly suitable for large thick-walled products.

The mold transfer vulcanization method uses the pressure of a press to inject rubber into a metal mold cavity, which has a high molding efficiency. The rubber injection holes at the beginning and end inject into the mold cavity. Due to the effect of friction force, the temperature of the rubber rises. Moreover, the rubber is preheated from beginning to end before injection molding. Therefore, the mold transfer method can be used to reduce the vulcanization time.

Complex rubber shock-absorbing finished products can be vulcanized by injection molding. As the injection molding part and the heating and pressurizing part of the injection molding machine are an integral part, the rubber is placed in the plunger in a strip or sheet form, and after being fully preheated, it is injected into the metal mold cavity under high pressure.

Starting from raw materials, strict quality control is implemented. Each batch of raw materials is inspected and qualified by laboratory technicians before entering the factory. Some rubber batching personnel mix materials in the required proportion. After the batching is completed, it is sent to the rubber mixing workshop and pressed into synthetic rubber sheets by the rubber mixer. After passing the inspection, the synthetic rubber sheets are sent to the shock absorber hose cutting workshop, where the staff cut them according to different models and sizes. After the blanking is completed, the forming process is carried out. After each shock absorber hose mold is inspected and found to be qualified, it is sent to the vulcanization workshop, where the staff place the mold. Put the mold into the vulcanizing machine. The vulcanizing machine will press the mold well. At this time, the vulcanizing machine is set to a constant temperature of 180 degrees, and the vulcanization is carried out for 40 minutes. After 40 minutes, remove the vulcanized shock absorber from the mold and test the integrity of the vulcanization of the shock absorber. Trim the edges of the vulcanized shock absorbers and place them in the semi-finished cable car after trimming. The semi-finished shock absorber hoses inside the cable car are sent to the flange assembly workshop, where the staff assemble the shock absorber hose flanges and the semi-finished shock absorber hoses into finished products. The staff of the quality inspection department randomly sample and test the pressure of the finished shock absorbers. The shock absorbers that pass the pressure test are packaged. The packaged finished shock absorbers are placed in the warehouse, waiting to be loaded onto vehicles for shipment.

Note: During vulcanization, the vulcanization time and temperature must be strictly controlled. Generally speaking, the crosslinking degree of rubber increases with the addition of light, while the modulus of rubber and the consumption coefficient of rubber decrease. Therefore, the vulcanization of rubber flexible joints must be thorough. Both under-vulcanization and over-vulcanization will cause the performance of the finished product to decline.

- Why Choose Between UPVC Pipes and HDPE Pipes?

- Why Is Ductile Iron Pipe Still the Safe Choice for Long-Life Water Networks?

- Which Pipeline Installation Machines and Tools Help Me Deliver Faster, Safer, and More Profitable Projects?

- Key points for quality inspection of ductile iron pipes

- Why do Carbon Steel Pipes keep winning tough industrial projects?

- What are the connection methods for ductile iron pipes?

About Us

Contact Us

No. 112, Jiefang Road, Lixia District, Jinan City, Shandong Province, China

Copyright © 2025 Shandong Epoch Equipment Co., Ltd. All Rights Reserved.