Email Us

What is a flange adapter? What is the operating principle of a flange adapter?

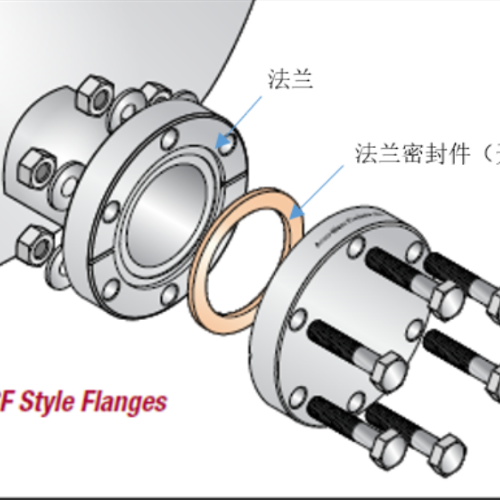

The flange adapter operates through its specialized design, enabling the connection of flanges with differing specifications or incompatible types to establish an interface between piping or equipment components. Flange adapter typically consists of bolting elements and a sealing gasket that work in concert to ensure joint integrity and stability. When connecting two dissimilar flanges via the adapter, bolts are tightened to compress the gasket, which simultaneouslFills gaps and seals the interface to prevent fluid/gas leakage;Transmits the applied compressive force across the flange faces;Maintains structural reliability by distributing mechanical loads and torsional stresses.

The sealing integrity and stability of flange adapters depend critically on their design and manufacturing precision. Dimensional accuracy and geometric compatibility with the target flanges are essential to ensure proper fit and effective sealing. Adapter materials must possess sufficient strength to withstand anticipated pressure and temperature loads while delivering reliable sealing performance. Common materials include metals such as carbon steel and stainless steel, or thermoplastics like PVC and polyethylene.

Flange adapter installation requires strict adherence to precision protocols: Begin with material validation (matching PN/Class ratings, inspecting EPDM gaskets at 50±5 Shore A) and surface preparation (degreasing flanges with acetone). During assembly, align components within ≤1° angular/≤1% DN radial tolerance, applying food-grade lubricant to rubber rings. Execute bolt tightening in cross-pattern sequence (e.g., 1-5-3-7-2-6-4-8 for 8-bolt flanges) using three-stage torque loading (30%→60%→100% final torque; e.g., M20 bolts at 340N·m for PN25). Post-installation, conduct 0.6MPa pneumatic tests (≤1% pressure drop) and vibration monitoring (<50μm amplitude). Critical safeguards include thrust force calculation (F=ρ·A·Δv/Δt) for concrete anchor blocks if F>50kN, dielectric isolation (insulating sleeves + PTFE gaskets >1MΩ resistance), and thermal expansion compensation (δ=α·L·ΔT with α=11.2×10⁻⁶ m/(m·℃)). Non-compliance with thrust verification or bypassing staged torque procedures risks catastrophic joint failure.

SHANDONG EPOCH EQUIPMENT CO., LTD. is a large-scale professional manufacturer in Shandong Province of China, adheres to the orientation of science and technology, environmental protection, quality and efficiency. At present, it has grown into a trans-regional and multi-industrial enterprise integrating such wide industries as design, development, production and export. Visit our website at https://www.epochpipeline.com/ to learn more about our products. For inquiries, you can reach us at sdepochwater@hotmail.com.epochpipeline@hotmail.com

- Why Choose Between UPVC Pipes and HDPE Pipes?

- Why Is Ductile Iron Pipe Still the Safe Choice for Long-Life Water Networks?

- Which Pipeline Installation Machines and Tools Help Me Deliver Faster, Safer, and More Profitable Projects?

- Key points for quality inspection of ductile iron pipes

- Why do Carbon Steel Pipes keep winning tough industrial projects?

- What are the connection methods for ductile iron pipes?

About Us

Contact Us

No. 112, Jiefang Road, Lixia District, Jinan City, Shandong Province, China

Copyright © 2025 Shandong Epoch Equipment Co., Ltd. All Rights Reserved.